Table of Contents

Difference Between Fans, Blowers and Compressors

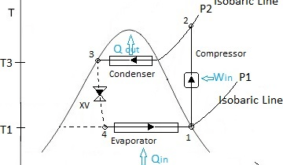

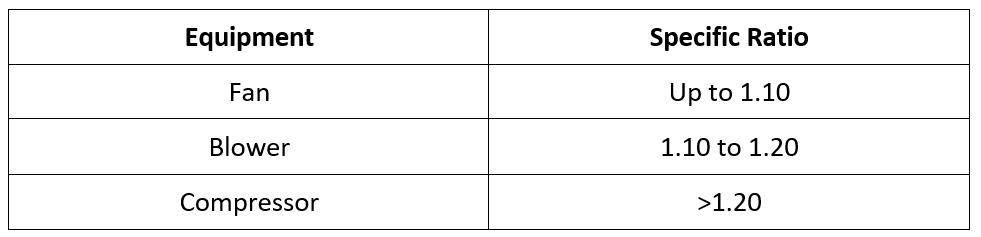

Fans, blowers and compressors are used to move fluid or air. They are differentiated from each other by ASME based on the specific ratio (![]() ).

).

Here, we will discuss about centrifugal fan which is widely used across many industries for ventilation, hot air circulation in furnaces, blowoff vessel off-gases in process industries…etc.

Working Principle of a Centrifugal Fan

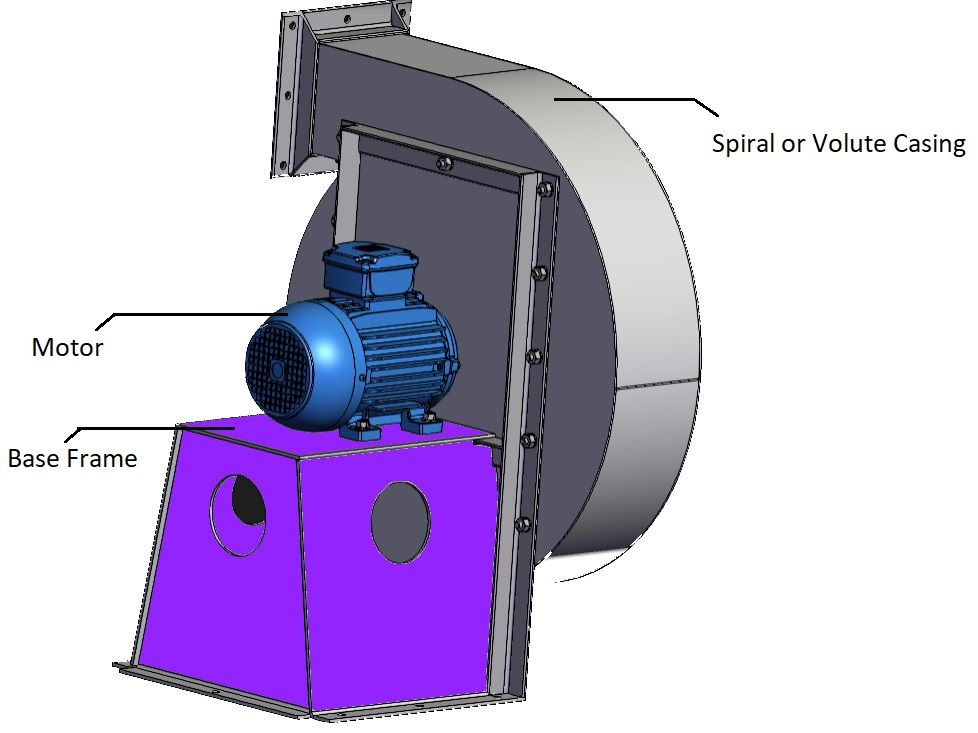

In general, “centri” means centre and “fuge” means away. It means away from the centre. A typical centrifugal fan consists of the following components.

Components of a Centrifugal Fan

- Eye of the impeller

- Impeller

- Spiral casing or volute casing

- Shaft

- Motor

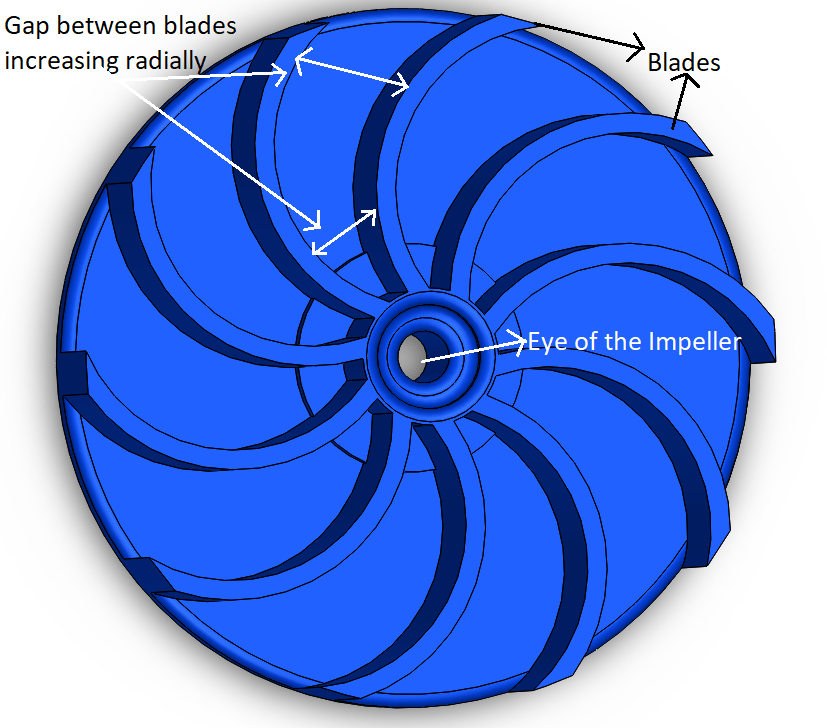

An impeller is a rotating part that consists of a series of blades as shown in figure 1. The impeller transfers the kinetic energy to the working fluid or air (Let us assume air is a working fluid in a fan) present in the impeller. When the impeller rotates, the working fluid is thrown away from the impeller due to centrifugal action. When the air passes between the series of blades, the kinetic energy of air is converted into static pressure.

As per Bernoulli’s theorem, when there is a flow through the gradually increasing cross-section, the kinetic energy or velocity gets converted into static pressure. Similarly, the circumferential gap between the two blades increases radially thus increasing the cross-section. Air with leftover kinetic energy from the impeller will be converted into static pressure while passing through the spiral casing (having a gradual increase in cross-section in the flow direction). When the air is thrown out from the blade tip, a gap or vacuum is created near the centre of the impeller called the eye of the impeller as shown in the figure. Thus, suction is created at the eye of the impeller.

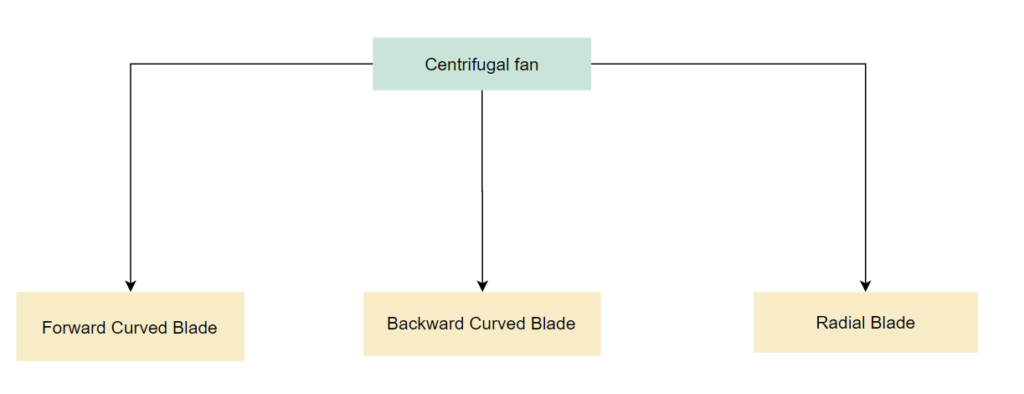

Types of Centrifugal Fans

Centrifugal fans are classified into three types based on different blade configurations installed on the impeller. They are

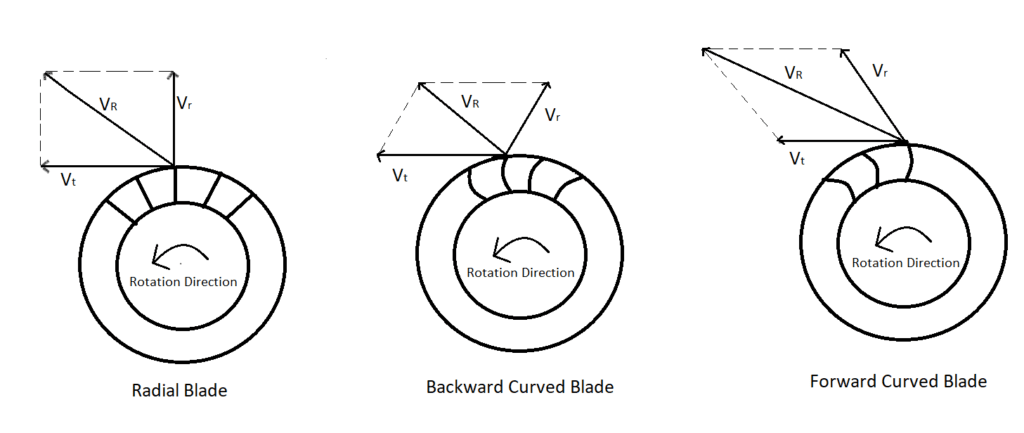

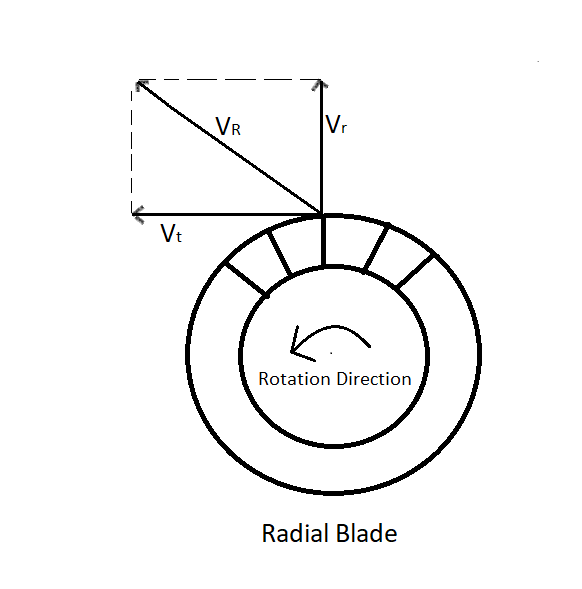

Note:

![]() = Tangential Velocity (Directly related to impeller speed i.e

= Tangential Velocity (Directly related to impeller speed i.e ![]() , where D= diameter of impeller, N is RPM

, where D= diameter of impeller, N is RPM

![]() = Resulting velocity of air leaving the blade tip

= Resulting velocity of air leaving the blade tip

![]() = Relative velocity of air leaving with respect to the blade.

= Relative velocity of air leaving with respect to the blade.

The above figures are drawn by assuming all the three are rotating at the same speed i.e., same ![]() .

.

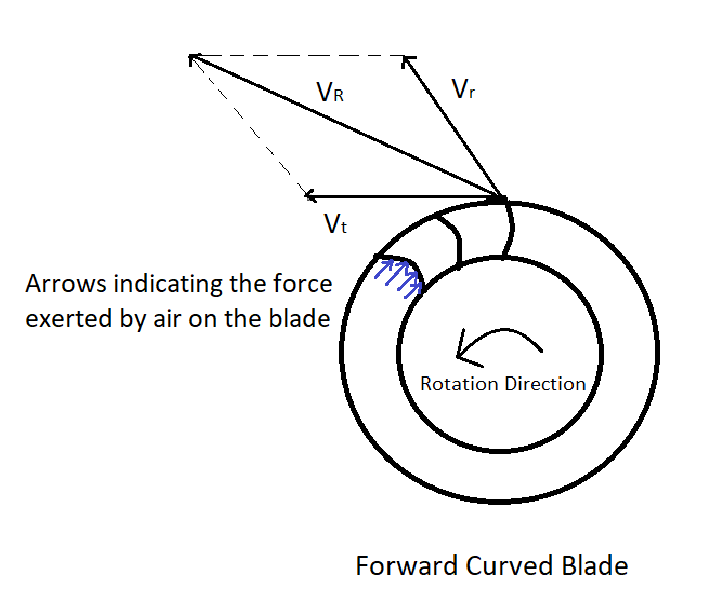

1. Forward Curved Blade

The curvature of the forward-curved blade faces towards the direction of rotation of the impeller as shown in Figure 4.

The length of the blade is relatively shorter as compared to radial and backward curved blades. Because the force exerted by the air on the blade (while the impeller is in rotation) is in the direction of the bend as shown in the following figure. Due to this, the structural integrity of the blade cannot be achieved by using a longer-length blade which can easily get bent at higher speeds.

The resultant velocity vector ![]() of the forward-curved blade (as shown in Figure 2) is the largest as compared to the radial and backward blades. The higher resultant velocity of air results in higher kinetic energy of air and faster will be the movement of air thus higher volume flow rates. For the same impeller speed, high airflow rates can be achieved in a forward-curved centrifugal fan. Thus, they are relatively smaller in size.

of the forward-curved blade (as shown in Figure 2) is the largest as compared to the radial and backward blades. The higher resultant velocity of air results in higher kinetic energy of air and faster will be the movement of air thus higher volume flow rates. For the same impeller speed, high airflow rates can be achieved in a forward-curved centrifugal fan. Thus, they are relatively smaller in size.

In another way, for a given volume flow rate, a forward-curved blade requires the lowest speed as compared to a radial and backward-curved blade centrifugal fan. It results in lighter construction (the lower the speed, the lower the centrifugal stress on the blades), and quieter operation.

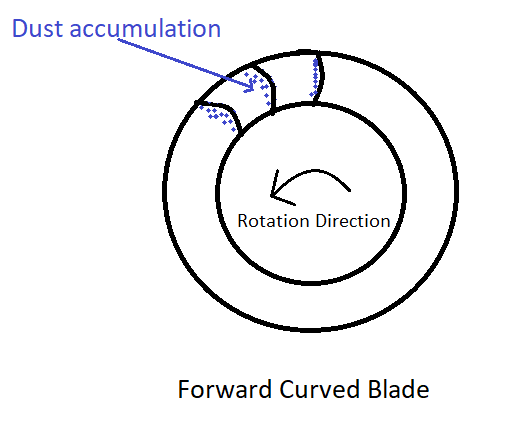

There is a possibility of dust accumulation if the air that is being handled is dirty as shown in the following figure 5. Due to dust accumulation, the effective cross-sectional area for the airflow reduces. Thus, reducing the flow capacity.

Performance Characteristics of Forward Curved Blade Centrifugal Fan

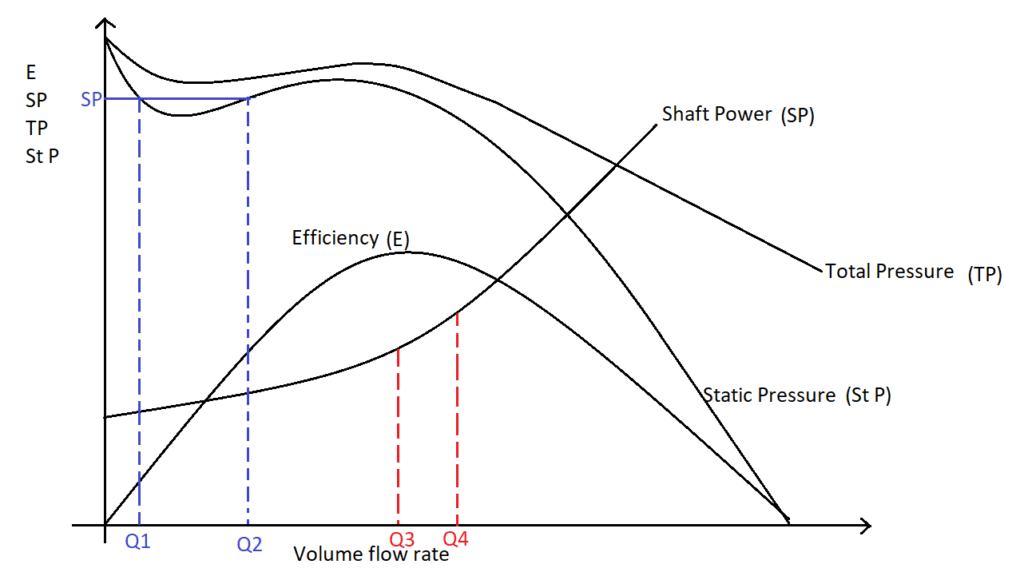

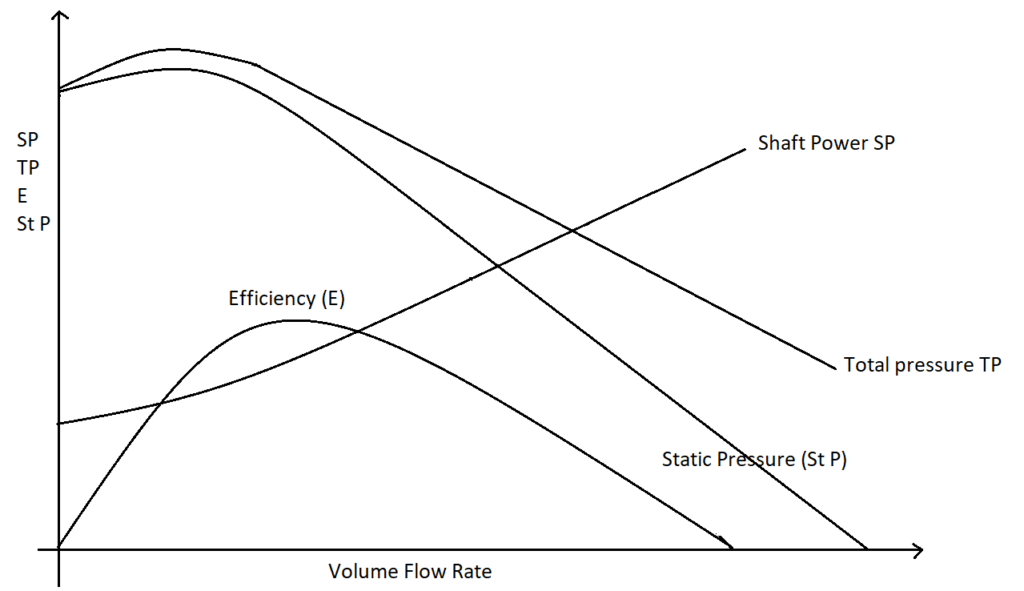

A performance characteristic of a centrifugal fan represents the change in power, efficiency, head developed or static pressure rise with respect to a change in volume flow rate through the centrifugal fan. The following figure represents the performance characteristics of a forward-curved centrifugal fan.

Conclusions from the above figure,

There is a significant dip in the static pressure curve. So, for the same developed static pressure (SP), there will be two different volume flow rates (Q1, Q2). So, a fan can flip over two possible flow rates for the same static pressure. This results in pulsating flow when the forward-curved blade centrifugal fan is chosen for low-volume flow rates.

Shaft power is proportional to the air volume flow rate. It means, that if the motor of this fan is designed for a particular flow rate (i.e., Q3) in case there is an increase in flow rate (i.e., Q4) due to a decrease in static pressure, the motor will be overloaded as shown in shaft power vs volume flow rate curve of figure 6. Since the velocity of air leaving the tip of the blade is highest in this fan, most of the kinetic energy of air cannot be converted into static pressure in the spiral casing. Thus, it has the lowest static efficiency.

![]()

Applications of Forward Curved Blade Centrifugal Fan

- Cannot be used in the mining or cement industry due to the possibility of dust accumulation in the blade curvatures.

- It is ideal for residential heating and cooling systems (i.e., Domestic air conditioner’s condenser cooling fans…etc), due to the quieter and high flow rates characteristics of forward-curved blade centrifugal fans.

- It is preferred in air filtration in clean rooms, and cooling applications in data centres where flow rate is of high importance as compared to the static pressure for maintaining a number of air changes and cooling purposes respectively.

- Due to low static efficiency, the air leaving from the fan will have high kinetic energy (i.e., high dynamic component as compared to static component) which results in high flow rates with less static pressure.

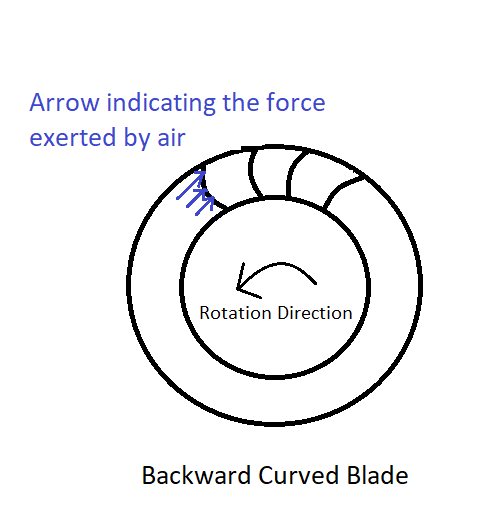

2. Backward Curved Blade

The curvature of the backward-curved blade faces in a direction opposite to the rotation of the impeller as shown in Figure 7. The length of the blade is relatively longer as compared to the radial and forward-curved blade because the force exerted by the air on the blade acts in a direction opposite to the bent (as shown in the following figure) which does not sacrifice the structural integrity, unlike forward-curved blade centrifugal fans.

The resultant velocity vector ![]() of the backward curved blade (as shown in Figure 3) is the smallest as compared to the radial and forward blade. For the same impeller speed, the lowest volume flow rate will be delivered by a backward-curved centrifugal fan.

of the backward curved blade (as shown in Figure 3) is the smallest as compared to the radial and forward blade. For the same impeller speed, the lowest volume flow rate will be delivered by a backward-curved centrifugal fan.

In another way, for a given volume flow rate of air, a backward curved blade centrifugal fan runs at the highest speed as compared to radial and forward curved blades. Thus, a backward curved blade centrifugal fan can be directly mounted to modern motors without the need for any speed reduction device like a gearbox. Since it is a high-speed impeller, the shaft and its rotor have to be balanced precisely otherwise a small unbalance or eccentricity will cause significant damage since centrifugal force is proportional to the square of speed. As a factor of safety, these fans are relatively heavier in construction.

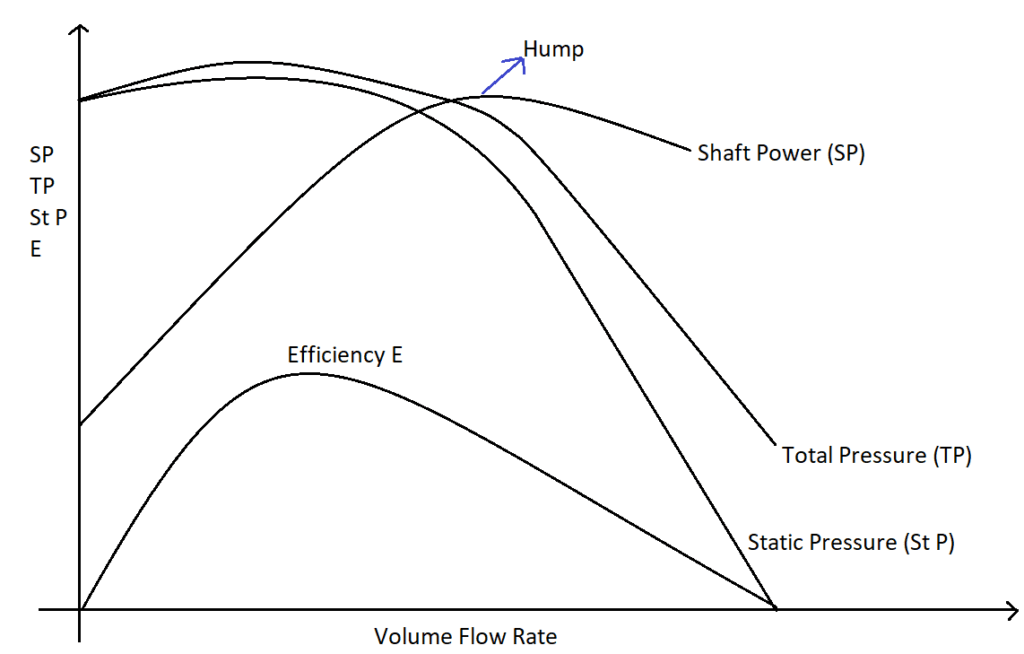

Performance Characteristics of Backward Curved Blade Centrifugal Fan

The following figure represents the performance characteristics of a backward-curved centrifugal fan.

Conclusions from the above figure,

The difference between static pressure and the total pressure is relatively less (shown in the above figure) as compared to radial and forward-curved blades. It means, that most of the kinetic energy transferred to air from the impeller gets converted into static pressure (That’s the function of a centrifugal fan).

As explained earlier, the circumferential gap between the two blades widens as we move away from the centre. Consequently, a longer blade results in a greater conversion of kinetic energy into static pressure. Thus, most of the kinetic energy of air gets converted into static pressure between the blades itself. Hence its static efficiency is high. Thus, backward curved blade fans can be used without a spiral casing for special cases like plug fans. The velocity of air leaving the blade tip is relatively low (due to conversion into static pressure) noise generation is also low.

The unique feature of the backward curved blade is the non-overloading characteristic. It is due to the hump in the shaft power vs volume flow rate curve as shown in figure 8. It means, if you design a motor based on the peak load (i.e., Load at the hump) even after a change in volume flow rate, the motor will never get overloaded. This characteristic is also known as a self-limiting characteristic.

There is no dip in the static pressure curve.

Applications of Backward Curved Blade Centrifugal Fan

- A plug fan is a special type of centrifugal fan. It does not have any casing to convert kinetic energy into static pressure because it uses a backward curved blade where most of the kinetic energy will be converted into static pressure before leaving the blades itself. (Due to longer blade length).

- High-pressure industrial applications like pneumatic conveying systems where high pressure is required to overcome the system resistance.

3. Radial Blade

Blades are straight without any curvature and oriented radially as shown in the following figure.

The geometry of the radial blade is such that solid particles like dust, and dirt. etc present in the working fluid will not stick to the blades whereas in forward-curved blades solid particles can settle in the curved portion of the blade. Thus, radial blade fans are best suitable for harsh environments and material handling applications. So, to withstand harsh environments, blades are made heavier and deeper than forward and backward-curved fans. The blades are simple in design as there are no complex curvatures.

Radial blade centrifugal fans are connected to their motors using a belt drive to transmit the power & motion between the motor and fan since these fans are subjected to shock loads due to material handling.

Performance Characteristics of Radial Blade Centrifugal Fan

The following figure represents the performance characteristics of a radial blade centrifugal fan.

Conclusions from the above figure

Exhibits the same shaft power characteristics as of forward-curved blade centrifugal fan.

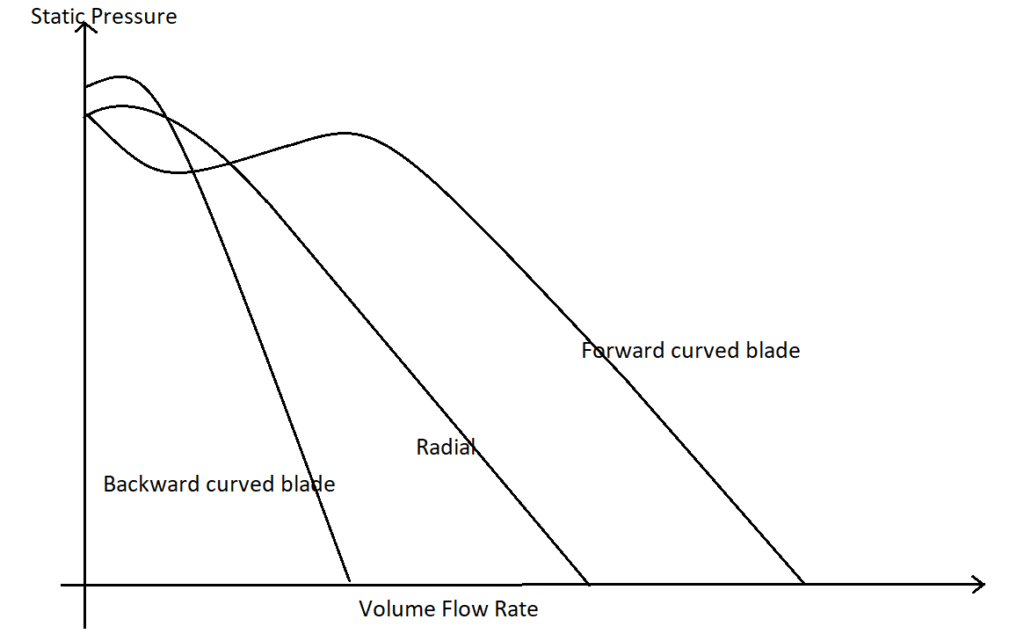

Characteristic curves of all three fans are drawn in one graph as shown in the following figure.

The radial blade is used to deliver low to medium airflow rates with medium to high static pressures as shown in the above figure.

Static efficiency will be in between of forward and backward curved blade.

Application of Radial Blade Centrifugal Fan

Material handling industries like mining and cement industries where the working fluid contains solid particles. These fans contribute to effective ventilation in underground mines, aiding in the removal of airborne particles and ensuring a safer working environment for workers.

FAQ

1. How do centrifugal fans work?

How do Centrifugal Fans Work? – The Mechanical Engineer (amechieneer.com)