Table of Contents

Interview Questions Part-5 (21 to 25)

21. What is the difference between Stress and Pressure?

| Stress | Pressure |

| Stress is an internal resistance force to the deformation per unit area | Pressure is an external force per unit area |

| Stress is a material property since it is the resistance induced by the material to the force applied | Pressure is independent of material property |

| Mathematical relation for stress | |

| SI unit | SI unit |

| Stress can be developed because of pressure since pressure is an external load, the material resists the load in the form of stress | Pressure cannot be developed because of stress |

| Stress cannot be measured directly by using any instruments but it can be calculated by measuring the deformation of material using a strain gauge. i.e., | Pressure can be measured directly using pressure gauges |

| Stress can be positive or negative depending on the direction of force applied. i.e., tensile or compression force | Pressure is always positive since the direction of pressure is always normal to the surface |

| Nature of stress can be compressive, tensile, shear or torsional depending upon the orientation of external force with respect to the surface of the material | Pressure is always compressive |

| The magnitude of stress at a point may not be the same in all the directions | The magnitude of pressure at a point is same in all the directions. |

22. What is the difference between an open and a closed impeller of a centrifugal pump?

| Open Impeller | Closed Impeller |

| Construction: Vanes (or blades) do not contain shrouds. | Vanes (or blades) contain shrouds on both sides. i.e., front and back of the impeller (shrouds are nothing but the plates fixed to the front and backside of the impeller) |

| Application: The impeller is free from clogging (since vanes are open) thus it is used in handling fluids containing solid particles. | Since the front and backside of the vanes are closed with shrouds, it is used in handling the clear fluids only otherwise impeller will clog. |

| Structural: Impeller cannot be used in heavy-duty applications since vanes are supported on the hub (near the impeller eye) only i.e., just like a cantilever beam. | Can be used in heavy-duty applications since the vanes are supported by the hub as well as the shrouds. |

| Performance: Poor efficiency because the flow is not guided between the vanes for effective conversion of kinetic energy into pressure. Lack of shrouds leads to axial fluid leakage between the vanes. | Relatively higher efficiency because there is no leakage of fluid across the vanes since the vanes are attached to the shrouds on both sides. |

23. What happens when a centrifugal pump runs at off- BEP? (i.e., away from the best efficiency point)

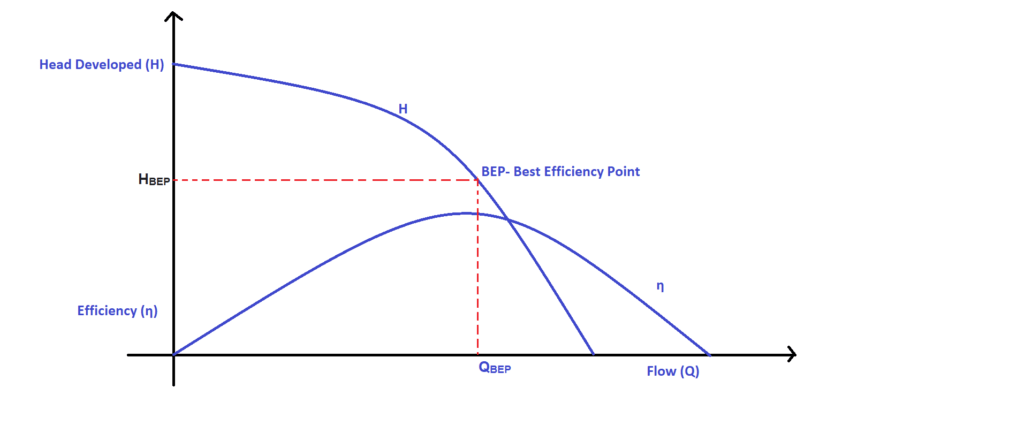

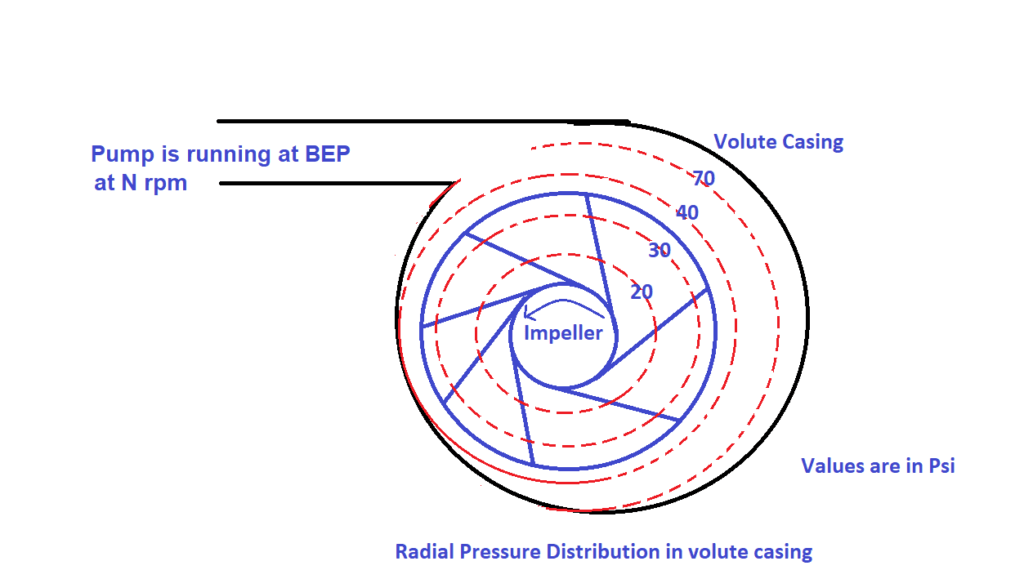

Best efficiency point: The combination of the head and flow rate of a pump that yields the highest efficiency for a specific impeller diameter. When the pump is operating at BEP, the radial pressure distribution is uniform circumferentially in the volute casing as shown in the figure-3.

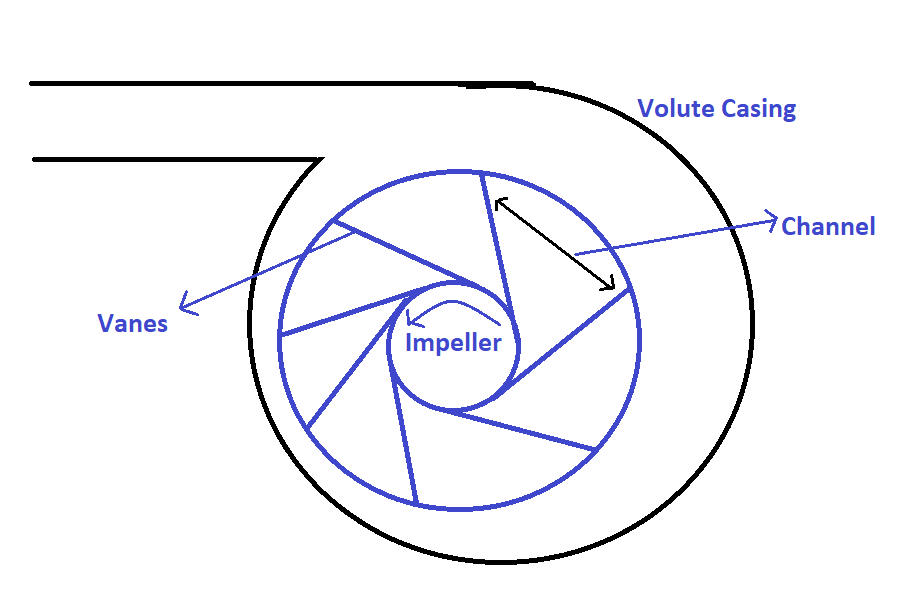

Consider a single volute casing of a centrifugal pump as shown in the following figure.

Note: The circumferential gap between the two blades is called a channel as shown in the following figure.

The pump is running at BEP:

A single volute of a centrifugal pump is designed for a uniform radial pressure distribution circumferentially at BEP as shown in the following figure.

As we move away from the centre of the impeller, the fluid pressure increases due to centrifugal action.

The pump is running at off- BEP:

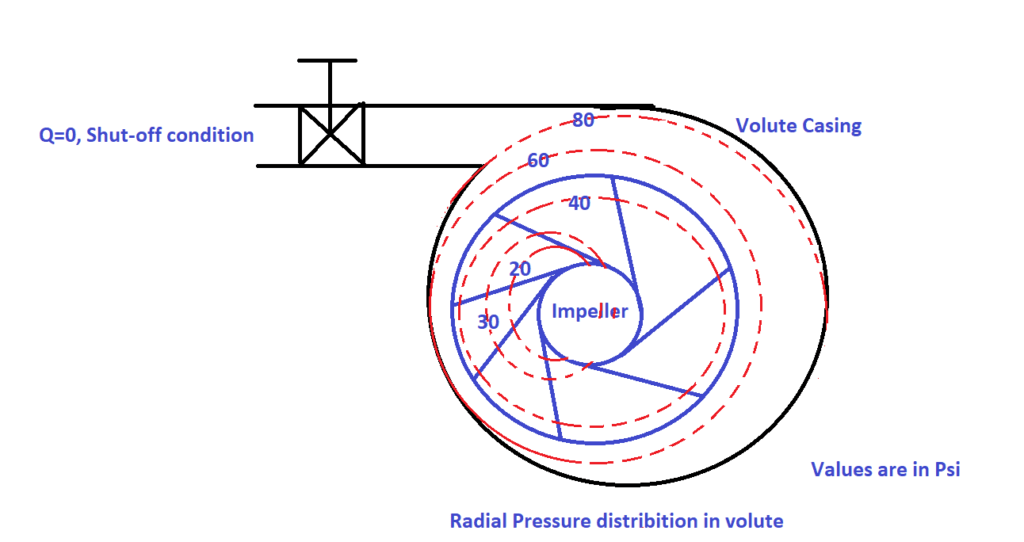

Consider a centrifugal pump running at off- BEP (assume that a pump is running at shut-off condition i.e., discharge valve is in closed condition (Q=0)). Though the discharge valve is in closed condition, the impeller delivers kinetic energy to the fluid in the volute casing and gets pressurized. The fluid undergoes churning action and recirculation randomly resulting in non-uniform pressure distribution circumferentially around the impeller as shown in the following figure.

Consequences of running a centrifugal pump at Off-BEP

The non-uniform pressure distribution leads to the generation of radial loads on the impeller. Since the pump is in running condition, the radial load is dynamic in nature resulting in the generation of vibration & noise and shaft deflection. These vibrations and radial loads deteriorate the life of the mechanical seal and bearings mounted on the shaft.

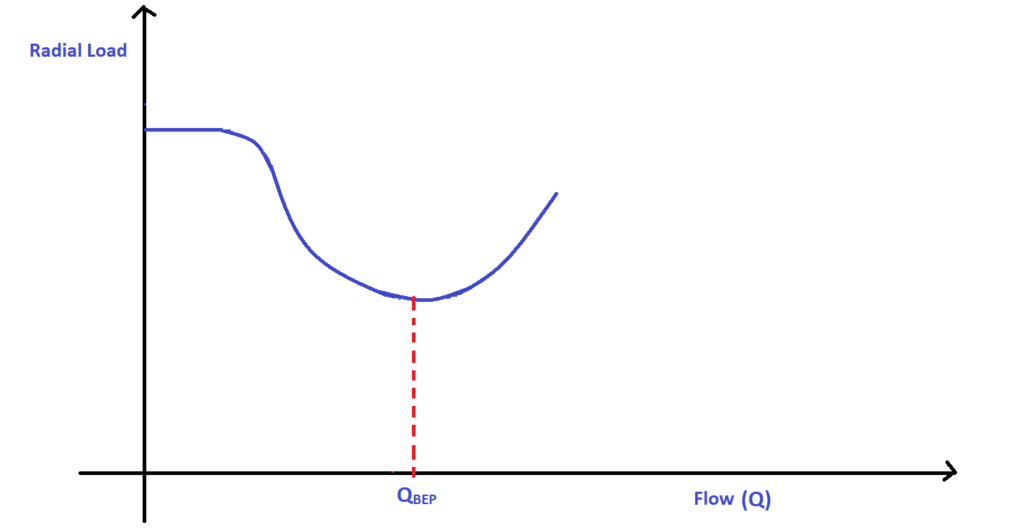

Note: The pump vibrates excessively at shutoff conditions as compared to the case of normal operation due to non-uniform radial pressure distribution. The following graph represents the radial load vs flow delivered by the pump.

The radial load increases as we move away from the BEP and reaches the highest at shut-off conditions.

24. How does the available Net Positive Suction Head (NPSHA) vary for flooded suction and suction lift?

Suction Lift

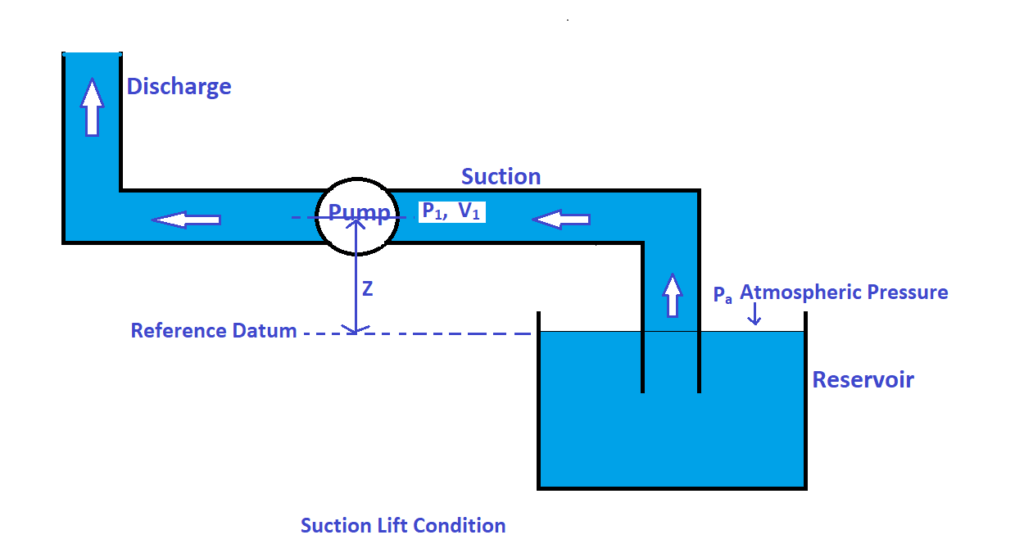

Consider a pump mounted above the reservoir to transfer the liquid as shown in the following figure.

The pressure ![]() at the inlet of the pump must be greater than or equal to the vapour pressure

at the inlet of the pump must be greater than or equal to the vapour pressure ![]() of the liquid being handled at a given temperature to avoid cavitation.

of the liquid being handled at a given temperature to avoid cavitation.

![]()

![]() (Written in terms of head)

(Written in terms of head)![]()

![]() …………………Eq-1

…………………Eq-1

The difference of the pressure head at the entry of a pump and the vapour pressure of the fluid at a given temperature is called NPSHA.

If the NPSHA is less, then the chances of cavitation are high.

By applying Bernoulli’s theorem between the surface of the liquid at the reservoir and the centre line of the pump,

![]()

Where ![]() represents the major head loss in suction pipe

represents the major head loss in suction pipe

![]() ……………..Eq-2

……………..Eq-2

By substituting the Eq-2 in Eq-1 we get,

![]() ………………..Eq-3

………………..Eq-3

Flooded Suction

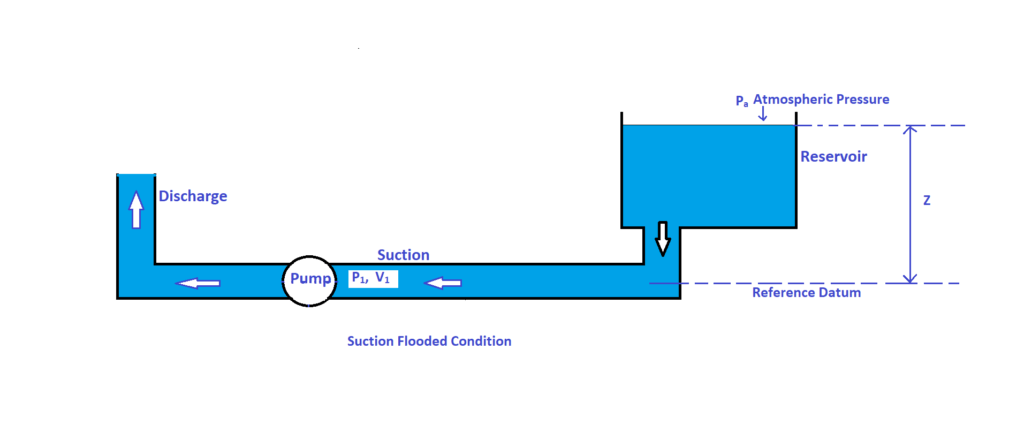

Consider a pump mounted below the reservoir to transfer the liquid as shown in the following figure.

By applying Bernoulli’s theorem between the surface of the liquid at the reservoir and the centre line of the pump,

![]()

![]() …………………….Eq-4

…………………….Eq-4

Substitute Eq-4 in Eq-1

![]() ……………..Eq-5

……………..Eq-5

Conclusion:

of flooded suction is greater than

of flooded suction is greater than  of suction lift because of positive elevation (+Z) of a reservoir.

of suction lift because of positive elevation (+Z) of a reservoir.- The lower the major head loss in the suction pipe, the higher will be the NPSH value.

of a centrifugal pump operating at a hill station will have relatively less value as compared to a similar pump operating at mean sea level. (As altitude increases,

of a centrifugal pump operating at a hill station will have relatively less value as compared to a similar pump operating at mean sea level. (As altitude increases,  reduces)

reduces)

25. Why does the pressure developed by a centrifugal pump is represented in terms of a head (meters)?

A centrifugal pump manufacturer does not know for what type of fluids the customer uses the pump to transfer it. The customer may use the same pump for handling the water for some time and slurry for some time. So, the manufacturer has to decide the parameter to specify the pump and to generate the performance curves that are independent of fluid properties. The head is the parameter that is independent of fluid property. i.e., ![]() . Mathematically the ratio represents the pressure developed per unit density of the fluid. Thus, whatever may be the density, the pressure is normalized mathematically by dividing with density. Hence the head developed by a centrifugal pump is independent of the density. Hence the performance of a pump remains the same whether it is a water or slurry.

. Mathematically the ratio represents the pressure developed per unit density of the fluid. Thus, whatever may be the density, the pressure is normalized mathematically by dividing with density. Hence the head developed by a centrifugal pump is independent of the density. Hence the performance of a pump remains the same whether it is a water or slurry.

Of course, you may have doubt that “what about the viscosity of a fluid?” But keep in mind that centrifugal pumps are not meant for handling high-viscosity fluids.