Lost your password? Please enter your email address. You will receive a link and will create a new password via email.

Please briefly explain why you feel this question should be reported.

Please briefly explain why you feel this answer should be reported.

Please briefly explain why you feel this user should be reported.

What is the purpose of Lip seal?

A lip seal is installed between the rotary shaft and the stationary housing. The lip seal acts as a shield between the lubricant and the atmosphere, it prevents the entry of dirt from entering the lubrication chamber. The lip seal acts as a seal as well by preventing the leakage of lubricant into thRead more

A lip seal is installed between the rotary shaft and the stationary housing. The lip seal acts as a shield between the lubricant and the atmosphere, it prevents the entry of dirt from entering the lubrication chamber. The lip seal acts as a seal as well by preventing the leakage of lubricant into the atmosphere.

See lessWhat is the meaning of EN-8 material?

EN stands for “Emergency Number”. There was intense demand for developing new materials during the world war era for manufacturing advanced weapons and machinery. Scientists and engineers involved in research do not have sufficient time to set standards for discovered materials having different cheRead more

EN stands for “Emergency Number”. There was intense demand for developing new materials during the world war era for manufacturing advanced weapons and machinery. Scientists and engineers involved in research do not have sufficient time to set standards for discovered materials having different chemical compositions and mechanical properties. Based on the chemical composition of a material, they had given emergency numbers, in short form “EN”.

See lessWhat is the application of lip seals?

Lip seals are preferred where the differential pressure between sealing fluid and atmosphere is less than 30 Kpa pressure. Lip seal is the weakest component in the lubrication system.

Lip seals are preferred where the differential pressure between sealing fluid and atmosphere is less than 30 Kpa pressure. Lip seal is the weakest component in the lubrication system.

See lessWhat is Mono block bearing?

Mono block bearing housing incorporates two bearings in single housing thus eliminating the misalignment issues between two bearings. It is generally used to support the shaft of overhung impeller of centrifugal fans. Figure-1: Sectional View of Mono Block Housing Figure-2: Typical Mono BlockRead more

Mono block bearing housing incorporates two bearings in single housing thus eliminating the misalignment issues between two bearings. It is generally used to support the shaft of overhung impeller of centrifugal fans.

Figure-1: Sectional View of Mono Block Housing

Figure-2: Typical Mono Block Housing

See lessWhat is the purpose of garter spring in Lip seal?

Garter spring ensures a consistent radial force on the lip of a lip seal due to tension in the spring such that the gap formed between shaft and the lip of lip seal due to wear of lip or radial run out of shaft can be covered. Figure: Garter Spring in Lip seal

Garter spring ensures a consistent radial force on the lip of a lip seal due to tension in the spring such that the gap formed between shaft and the lip of lip seal due to wear of lip or radial run out of shaft can be covered.

Figure: Garter Spring in Lip seal

See lessIs a lip seal dynamic or static?

Lip seal is a dynamic seal since there is a relative motion between the mating surfaces. Generally, lip type seals are used to seal the radial gap between rotating shaft and stationary housing to prevent the leak of lubricants like oil or grease as well as it prevents the ingression of dirt or foreiRead more

Lip seal is a dynamic seal since there is a relative motion between the mating surfaces. Generally, lip type seals are used to seal the radial gap between rotating shaft and stationary housing to prevent the leak of lubricants like oil or grease as well as it prevents the ingression of dirt or foreign particles into the oil chamber.

Figure: Typical Lip Seal

See lessWhat is Pillow block bearing?

Pillow block is a type of bearing housing with included anti-friction bearings to support the shaft. Pillow block housing is classified further based on the type of bearing installed like spherical roller bearing, ball bearing. Etc. Figure: Typical Pillow Block Bearing

Pillow block is a type of bearing housing with included anti-friction bearings to support the shaft. Pillow block housing is classified further based on the type of bearing installed like spherical roller bearing, ball bearing. Etc.

Figure: Typical Pillow Block Bearing

See lessWhat is Plummer block bearing?

Plummer block is a type of bearing housing like pillow block, but the Plummer block is supplied without bearings. Anti-friction bearing of suitable choice can be used depending on the application.

Plummer block is a type of bearing housing like pillow block, but the Plummer block is supplied without bearings. Anti-friction bearing of suitable choice can be used depending on the application.

See lessWhat is vibration analysis?

Every rotating machinery generates some sort of vibration due to various defects like unbalance in the impeller, eccentricity in the impeller, misalignment between motor and pump, structural looseness, bearing defect... etc. Every defect (above mentioned) generates vibration at a unique frequency. GRead more

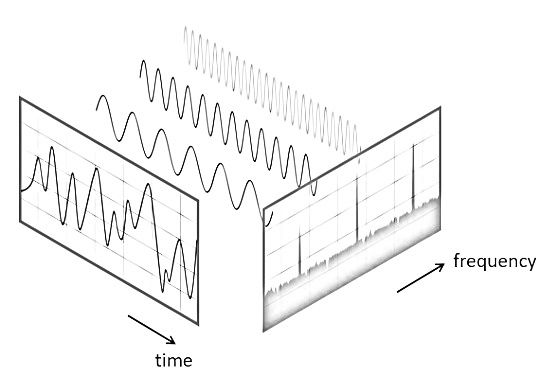

Every rotating machinery generates some sort of vibration due to various defects like unbalance in the impeller, eccentricity in the impeller, misalignment between motor and pump, structural looseness, bearing defect… etc. Every defect (above mentioned) generates vibration at a unique frequency. Generally, the measured vibration signal of real-world equipment is complex, and it is in the time domain. i.e., Amplitude Vs Time as shown in the following figure.

To diagnose the source of the defect the real-world vibration signal has to be transformed to the frequency domain using the Fourier transform. The maximum amplitude corresponding to a particular frequency reveals the source of the defect as shown in the following figure.

The process of transforming the real-world vibration signal from the time domain to the frequency domain and troubleshooting the source of the defect is called vibration analysis.

See lesswhat can vibration analysis detect?

Let us consider a centrifugal pump is coupled to a motor and it is in running. Vibration analysis can detect following defects from a running centrifugal pump. Misalignment between motor and pump Bent shaft as well as location of bend Faulty bearing (Dent in inner race, dent in outer race, dent in tRead more

Let us consider a centrifugal pump is coupled to a motor and it is in running. Vibration analysis can detect following defects from a running centrifugal pump.

- Misalignment between motor and pump

- Bent shaft as well as location of bend

- Faulty bearing (Dent in inner race, dent in outer race, dent in the ball/roller,

- Impeller unbalance

- Eccentricity in impeller

- Structural looseness

- Resonance

- Mechanical looseness

- Pipe strain

- Cavitation

See less