Lost your password? Please enter your email address. You will receive a link and will create a new password via email.

Please briefly explain why you feel this question should be reported.

Please briefly explain why you feel this answer should be reported.

Please briefly explain why you feel this user should be reported.

How does closing the suction valve of a running centrifugal pump affect cavitation?

Closing the suction valve of a centrifugal pump while it's running significantly increases the risk of cavitation. Here's why: For the mathematical relation of NPSH (available), you can refer to this link From the NPSH relation as mentioned in the above link, as the velocity of the fluid in the suctRead more

Closing the suction valve of a centrifugal pump while it’s running significantly increases the risk of cavitation. Here’s why:

For the mathematical relation of NPSH (available), you can refer to this link

The following graph represents the pressure profile without cavitation.

The following graph represents the pressure profile with cavitation.

- Bubble Collapse: As the liquid moves through the impeller, these bubbles collapse violently when exposed to higher pressure zones.

- Pump Damage: The collapsing bubbles create shockwaves that can damage the impeller, housing, and other pump components.

See lessWhy response spectrum is represented in acceleration vs frequency?

Force and Stress Generation: Acceleration directly represents the forces in the structure. From Newton’s second law of motion, the force acting on the structure is directly proportional to its mass and its acceleration. The higher the acceleration of ground motion, the higher the induced force in thRead more

Force and Stress Generation: Acceleration directly represents the forces in the structure. From Newton’s second law of motion, the force acting on the structure is directly proportional to its mass and its acceleration. The higher the acceleration of ground motion, the higher the induced force in the structure. Which in turn generates higher stresses in the structure.

Energy Transfer: The rate of energy transfer to the structure is proportional to the acceleration of the ground motion. Earthquake generates seismic waves which carry energy. The energy is transferred to the structures through ground motion. According to the work-energy principle, the work done on a structure is equal to the change in its kinetic energy. The work done on the structure is the product of the Force it exerts on the structure and its displacement. As we know force is proportional to the acceleration of ground motion, the higher the acceleration greater the force and work done on the structure hence the faster the rate of transfer of kinetic energy.

See lessWhat is the difference between CF8M and SS316 material?

CF8M and SS 316 are both austenitic stainless-steel alloys with similar chemical compositions and mechanical properties. But there are some key differences as follows. CF8M SS316 CF8M is a cast stainless steel. It means CF8M is produced by pouring molten metal into a mould. SS 316 is wrought stainleRead more

CF8M and SS 316 are both austenitic stainless-steel alloys with similar chemical compositions and mechanical properties. But there are some key differences as follows.

What is the difference between single and double mechanical seals?

Feature Single Mechanical Seal Double Mechanical Seal Number of seal faces One Two Buffer fluid No Yes Leakage potential Higher Lower because the backup Seal assists in preventing the leak in case of failure. Reliability Lower Higher because of having an extra layer of protection (i.e. back up seal)Read more

What is Zero Period Acceleration (ZPA)?

Zero period Acceleration (ZPA) refers to the spectral acceleration of the zero-time period structure under earthquake excitation. In other words, the zero-time period structure means the structure has a very high natural frequency (i.e. f=1/T). Since natural frequency is proportional to $\sqrt (stifRead more

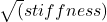

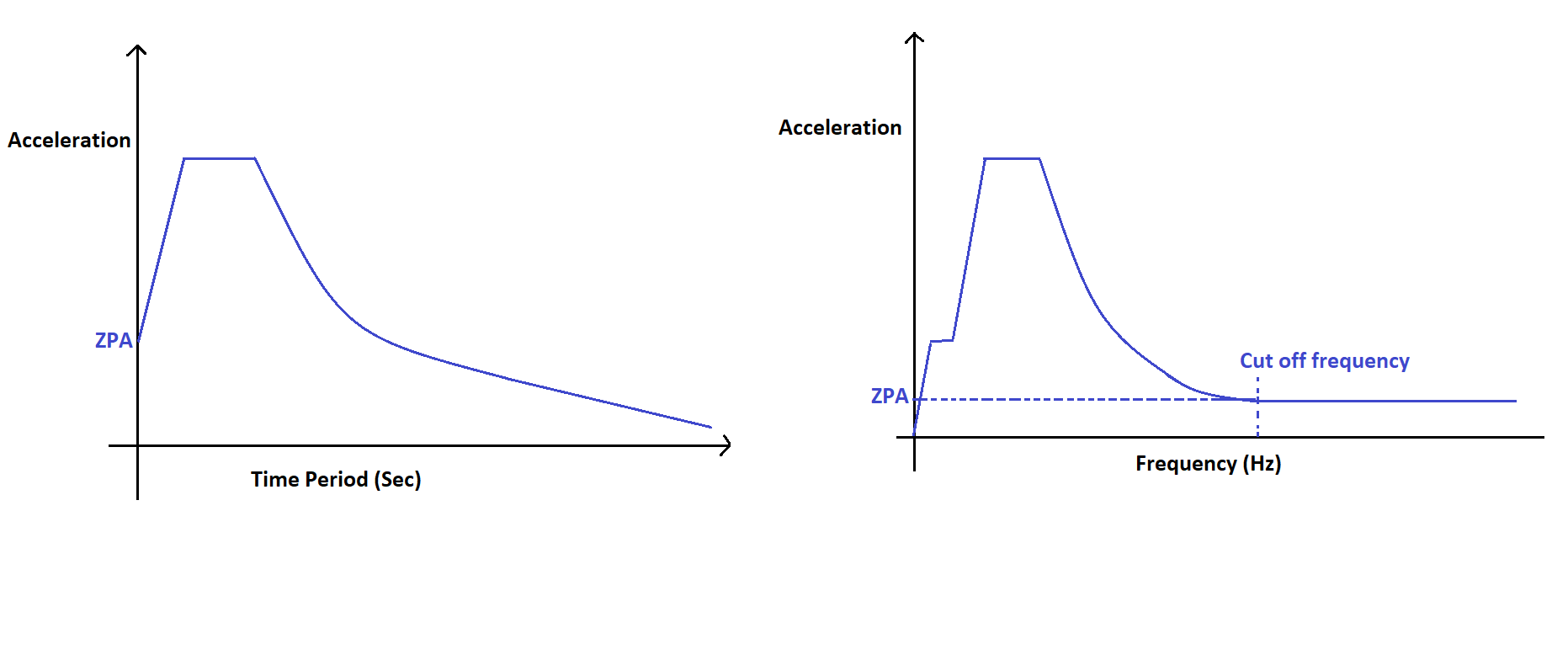

Zero period Acceleration (ZPA) refers to the spectral acceleration of the zero-time period structure under earthquake excitation. In other words, the zero-time period structure means the structure has a very high natural frequency (i.e. f=1/T). Since natural frequency is proportional to the structure having very high stiffness or a rigid structure will have a high natural frequency. ZPA has the value same as ground acceleration because if the structure is rigid, it will accelerate with the same magnitude of excitation acceleration.

the structure having very high stiffness or a rigid structure will have a high natural frequency. ZPA has the value same as ground acceleration because if the structure is rigid, it will accelerate with the same magnitude of excitation acceleration.

See lessWhat is floor response spectrum?

The design response spectrum helps in analysing the seismic behaviour of the primary structure. However, it cannot be used for analysing the behaviour of the secondary structure or a component mounted in the primary structure. Because the base acceleration seen by a tank mounted on the second floorRead more

The design response spectrum helps in analysing the seismic behaviour of the primary structure. However, it cannot be used for analysing the behaviour of the secondary structure or a component mounted in the primary structure. Because the base acceleration seen by a tank mounted on the second floor of the primary structure is not the same as the original ground acceleration of a primary structure. The primary structure acts as a band pass filter because the primary structure will not excite to very low frequencies or very high frequencies as compared to its natural frequency. Hence the primary structure will allow the earthquake signals having a frequency content close to its natural frequency. The peak responses of a particular floor at a given elevation are related to the natural frequency of the primary structure. The response of the tank on floor-1 is not similar to that of the same tank on floor-2 of the same primary building. Hence the floor response spectra are developed for different floors of the primary structure. The floor response spectra are drawn in a similar manner as that of the design response spectrum by drawing the envelope over the peaks of past response spectra.

See lessWhat is the design response spectrum?

The response spectrum which is used for the seismic analysis of a new structure for an anticipated or upcoming earthquake. From the past seismological data of a particular location, a single response spectrum was drawn using a single earthquake signal alone cannot be used for analysing the behaviourRead more

The response spectrum which is used for the seismic analysis of a new structure for an anticipated or upcoming earthquake. From the past seismological data of a particular location, a single response spectrum was drawn using a single earthquake signal alone cannot be used for analysing the behaviour of new structures for future earthquakes. Because Earthquake – A having the peak ground acceleration amplitude at a certain frequency is never Similar to Earthquake – B having the same peak ground acceleration value at a different frequency. Hence no two earthquakes are similar to each other. The stresses induced in a building structure having a natural frequency closer to that of earthquake – A is higher as compared to the stresses induced in the same building structure due to earthquake – B which has a significant frequency component far away from the natural frequency of the building. To overcome this, the past 25 numbers of earthquake signals of a particular location are considered and their individual response spectrum is plotted in the same Vs frequency plot. The envelope drawn over the Peaks of all 25 Response spectra is called the design response spectrum. The number of previous earthquakes considered for plotting the design response Spectrum may vary from standard to standard. The design response spectrum curve is smooth in contrast to the spiky response spectrum as shown in the figure below.

Vs frequency plot. The envelope drawn over the Peaks of all 25 Response spectra is called the design response spectrum. The number of previous earthquakes considered for plotting the design response Spectrum may vary from standard to standard. The design response spectrum curve is smooth in contrast to the spiky response spectrum as shown in the figure below.

The design response spectrum can be plotted in vs frequency plot or

vs frequency plot or  vs Time period plot as shown in the figure below.

vs Time period plot as shown in the figure below.

See lessWhether IGC practice – A test is alone sufficient to judge the susceptibility of the material to intergranular corrosion?

IGC practice - A test rapid screening test to test the susceptibility of austenitic stainless steel to IGA. Based on the test results of IGC practice - A, the material can be accepted or suspected but not rejected. Hence practice - A must be accompanied by some other tests to calculate the corrosionRead more

IGC practice – A test rapid screening test to test the susceptibility of austenitic stainless steel to IGA. Based on the test results of IGC practice – A, the material can be accepted or suspected but not rejected. Hence practice – A must be accompanied by some other tests to calculate the corrosion rate. By comparing the calculated corrosion rate and the allowable corrosion rate, the material can be accepted or rejected.

See lessWhen the IGC practice- C test is preferable?

The practice-C test is preferable when the intergranular corrosion is because of chromium depletion due to intergranular precipitation of chromium carbide and corrosion in intermetallic phases i.e sigma phase. The presence of high chromium content in stainless steel or any ferrite stabilizers acceleRead more

The practice-C test is preferable when the intergranular corrosion is because of chromium depletion due to intergranular precipitation of chromium carbide and corrosion in intermetallic phases i.e sigma phase. The presence of high chromium content in stainless steel or any ferrite stabilizers accelerates Delta-ferrite to Sigma phase transformation.

See lessWhat is IGC practice C test?

ASTM A262 standards have 5 different corrosion tests to test the susceptibility of Austenitic stainless steel to intergranular corrosion. IGC practice - C is one of those 5 tests. IGC practice- C involves the following steps: a. The austenitic stainless-steel sample is dipped in boiling, 65% NitricRead more

ASTM A262 standards have 5 different corrosion tests to test the susceptibility of Austenitic stainless steel to intergranular corrosion. IGC practice – C is one of those 5 tests.

IGC practice- C involves the following steps:

a. The austenitic stainless-steel sample is dipped in boiling, 65% Nitric acid for 48hrs duration.

b. After the first cycle, the sample is weighed to know the loss of weight due to corrosion. The loss is forecasted and expressed in terms of mills per year [Mpy].

c. The same cycle is repeated for the next 4 times. So in total, 240 hrs test duration in 5 different intervals. Each interval constitutes 48 hrs.

See lessd. The weight loss is calculated for all 5 cycles and an average value is found out.

e. The average value should be less than the allowable value to accept the material. In general the allowable corrosion rate followed industry is 18 Mills per year (Mpy)